Selecting The Most Efficient Degreasing Solvents

Selecting The Most Efficient Degreasing Solvents

Companies which make use of low volume of degreaser can also use any kind of degreaser they want even if these are canceled by EPA or Environment Protection Agency. However, those companies which make use of high volume of degreaser or live in a Low Emission Zone, where the emission of chemicals are found in the Clean Air Act is strictly monitored, should use the solutions which are safety to prevent paying fines from EPA.

Degreasing solvents which have PD-680 should not be used by companies which functions in a low emission zone, or utilize a large volume quantity of industrial degreaser. It must use cleaners which are safety not just for the people around but for the whole environment too. When choosing the right solution, you can follow the tips below:

It is best to choose an organic solution

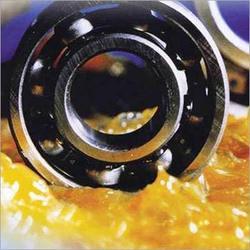

Lubricators Tips for The Average Joe

According to environmental views, choosing an organic cleaner than toxic cleaner is the best. You can use organic solutions that can be degreasers to remove tar, oil, bitumen, and other difficult to erase substances.

The Path To Finding Better Lubricators

You must go for a solution with low VOCs

There are organic solutions which can be good for the whole environment however, they can still be dangerous to humans as well as animals when they have high level of Volatile Organic Compounds. These have carbon chemicals which vaporizes at room temperature. Working with good ventilation system and outfit for the workers will provide safety to the workers, however, the first solution should have low levels of the compounds.

Opt for an environment-friendly solution

In case, you are having difficulty looking for an organic industrial degreasing solution, you next best choice is to have an environment-friendly solution. Even if there are solution which have MIL-PRF-680 formulation that is harmful for the environment, it is still safer compared to benzene saturated mineral spirits. If the companies choose environment-friendly solutions, this will hinder them from paying the EPA fines and negative reputations it gives.

Choose a high flash point

Flash point is referred to the solution that ignites at certain temperature. Aside from the fact the low flash point can be dangerous for certain degreasing applications like cleaning and energized motors, low flash point can also give storage problem.

If there is fire that goes to the storage room, it is flammable which may ignite and burn the whole building. This is the reason why it best to select an inflammable solution. However, this is proven impossible which is why you should determine if it has high flash point.

Selecting an industrial degreasing solution for long-term use should have important considerations like how the degreasers are made in regards with chemicals, VOCs, and flash point. Choose an industrial degreaser that has safety profile for both humans and environment.